Yao Yinliang, director of the Shaanxi Provincial Decision-making Advisory Committee and his team led the investigation of Magnesium High Magnesium Nobel Prize (Tongchuan) New Materials Co., Ltd. and Shekht Manno Prize New Materials Research Institute

On the morning of August 13, Yao Yinliang, director of the Shaanxi Provincial Decision Advisory Committee, and Xu Kewei, director of the Xi’an Decision Advisory Committee, and other leaders investigated the Shekht Manno Prize New Materials Research Institute and Magnesium High Magnesium Nobel Prize (Tongchuan) New Materials Co., Ltd. . Zeng Fanhong, chairman of Magnesium Nobel Prize (Tongchuan) New Materials Co., Ltd. and executive dean of the Shekhtman Nobel Prize New Materials Research Institute, accompanied the reception throughout the process. Professor Xu Chunjie from Xi'an University of Technology, Tu Tao, general manager of Magnesium High Magnesium Nobel Prize (Tongchuan) New Materials Co., Ltd., and deputy general managers Tian Jun and Xu Xiaohong participated in the event.

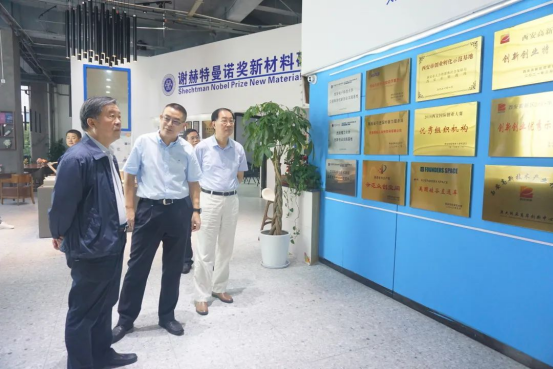

After coming to the exhibition hall on the first floor of the founder Makerspace, Director Yao Yinliang asked about the current operation and key incubation projects of the founder Makerspace in Xi'an, and learned about the development history of the founder's Makerspace and the progress made in incubation and cultivation. And the honor obtained.

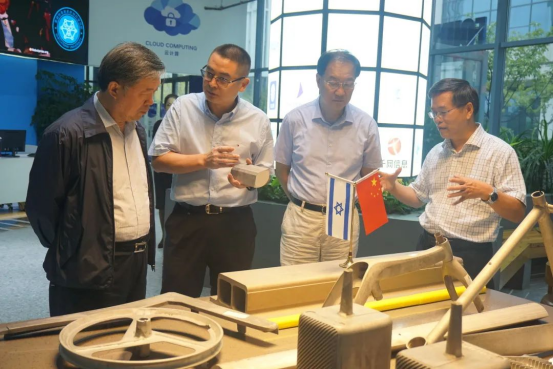

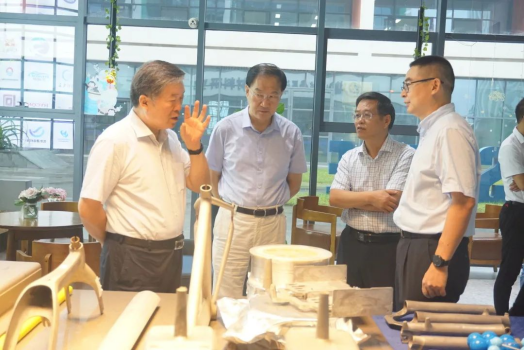

Under the guidance of chairman Zeng fanhong, director Yao yinliang came to the product exhibition area of New Materials Research Institute of Sheikh temano award. Chairman Zeng fanhong introduced the process technology and main uses of magnesium alloy castings and wire products. At present, the research institute mainly adopts the mode of combining Nobel Prize winning technology with advanced processing technology in Israel, which solves the shortcomings of "magnesium" metal in strength and toughness, room temperature plastic deformation ability, corrosion resistance and so on, and comprehensively improves the comprehensive properties of "magnesium" materials. These prepared high-strength and tough magnesium alloy materials can be used to manufacture parts with ultra-high strength requirements and directly replace high-strength aluminum alloys, especially for high-end equipment manufacturing industries such as aerospace, military industry, transportation and so on.

Director Yao yinliang said that he wanted to further understand Zeng fanhong's team's magnesium alloy additive manufacturing, rapid solidification, semi-solid injection molding and other molding technologies; Chairman Zeng fanhong told director Yao that the additive manufacturing and forming technology of the team mainly serves aerospace, aviation, military industry and other fields, and can provide products with a size of less than 2000m * 1500mm; The semi-solid injection molding technology can realize the mass production of civil products. Subsequently, the two sides conducted in-depth communication and exchange in the conference room on the second floor

At the symposium, chairman Zeng fanhong first reported in detail to director Yao yinliang and his party on the original intention and development process of the establishment of Sheikh temano award new materials research institute and MgO magno Award (Tongchuan) new materials Co., Ltd., as well as the work and achievements in the transformation of scientific and technological achievements, introduction of high-end talents of foreign experts and industrialization process in recent years.

Among them, relying on the 2011 Nobel Prize winner in chemistry, quasicrystal discoverer, Professor Dan shechtman team of Israel Institute of technology and Professor Xu Chunjie team of Xi'an University of technology, the Institute integrates high and new technology, research foundation and human resources, and adopts the production university research mode to introduce foreign high-end technology for achievement transformation. Magnesium and high magnesium focus on magnesium alloy additive manufacturing technology, rapid solidification technology and semi-solid injection molding technology. It mainly produces high strength and toughness magnesium alloy materials and products, which can be used in aviation, aerospace, military industry, automobile, biomedicine, high-end preparation and other fields. It provides a strong guarantee for the rapid development of China's intelligent manufacturing in terms of green, weight reduction and lightweight.

Finally, director Yao yinliang compared the performance and industrialization process of MgO High Magnesium Company's products with other research institutions and companies at home and abroad, and affirmed the company's technical breakthrough in improving the combination of damping resistance, electromagnetic shielding and other properties of high strength and toughness magnesium alloy. Leaders pointed out that the provincial government attaches great importance to the deep processing, R & D and production of magnesium alloy, and pointed out that the highlight of the company lies in the preparation technology of magnesium alloy wire and the processing and production of 3D printing parts of magnesium alloy with complex structure. In view of the company's lack of market pain points such as mass orders, director Yao said that the government would strengthen coordination, assist enterprises to connect market resources, and give constructive opinions on the company's market and development prospects. At the same time, he expressed the hope to see the good news of the company's listing as soon as possible and add a heavy color to the development of magnesium alloy industry in our province.

MgO MgO Nobel Prize (Tongchuan) new material Co., Ltd. is a high-tech new material enterprise focusing on the R & D, production and sales of high-strength and tough magnesium alloy. Relying on the quasi crystal discoverer, Professor Dan shechtman, the winner of the 2011 Nobel Prize in chemistry, the R & D team of Israel University of technology and the team of Professor Xu Chunjie, the New Materials Research Institute of Sheikh temano prize of Xi'an University of technology, the company focuses on magnesium alloy additive manufacturing technology, rapid solidification technology and semi-solid injection molding technology. It provides high strength and toughness magnesium alloy materials and products for aviation, aerospace, military industry, automobile, biomedicine, high-end preparation and other fields. Let China's intelligent manufacturing develop rapidly in terms of green, weight reduction and lightweight.